da Vinci 1.0 Pro Feed Mod II |

|

08-Apr-2017 |

|

| (Click on images for a larger view) | |

|

This is the squeal to my "da Vinci 1.0 Pro Feed Mod". I wasn't really happy with the original modification I made because when the extruder was at the front of the bed the copper tube pointing forward put a strain on the PTFE tubing. But it was a quick fix and kept me printing. I finally decided to see if I could make an improvement.

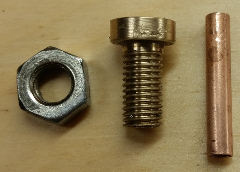

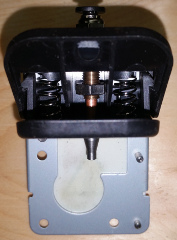

I decide to remove that plastic piece on top of the extruder assembly as it doesn't appear to have any useful purpose that I can discern. I also removed the rubber tube guide that extended through the bracket that guided the filament. That then gave me some options. At first I was going to machine a fitting for the quick connect to screw into and that fitting would then extend through the hole where the rubber guide tube was. I was then going to make a metal plate that would go on top of the bracket to secure the fitting in place. But while machining the fitting I decided to thread the OD of the fitting that extends through the guide hole. |

|

|

|