|

|

|

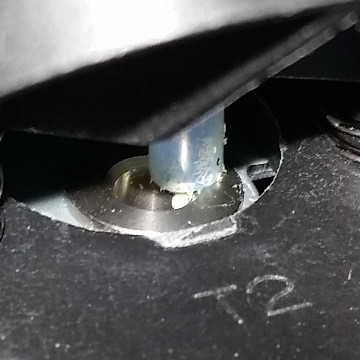

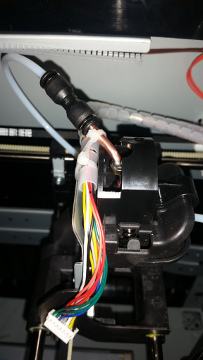

The filament guide tubing was pushed up and out of the hole and moved sideways effectively blocking the tube.

|

|

|

|

|

|

Close up showing the filament guide tube not in the fittings hole thus blocked.

|

|

|

|

|

After placing the filament guide tube back into the fitting this then happened. Half way through a make the filament was no longer feeding. By the time I caught it the extruder was a good 1/8" above what ABS had been laid down. This time the guide tube pushed up out of the hole so far it caused the short section of the guide tube to kink and rupture. It pushed up so far you could not see it from the side as shown in the previous two images. Needless to say the filament was pinched in that kink and could not feed.

|

|

|

|

|

Well at this point I was dead in the water. Figured this was easy enough to fix and did not want to go through a protracted warranty claim. So I measured the tubing OD & ID, turned out it's 0.154"x0.120", otherwise probably known as 5/32"x1/8", so then did some Google'n. Didn't take me too long to figure out that PTFE tubing seems to be the tubing of choice for this application and found some at Maker Geeks. Not too far away so might have it in a day or two. First thing in the morning I ordered some.

But then I got to thinking about how to make the short piece of guide tubing more rigid so this would not happen again. Having the feeder servo 10-20" from the extruder doesn't hit me as a great design IMO. Pushing filament that far through flexible pathways no doubt reduces feed amount accuracy. I always thought the feed servo was right by and part of the extruder assembly.

Well anyway, back to preventing this from happening again. I thought of getting some K&S brass tubing that could slide over this short piece of PTFE tubing. I realized that even though the wall thickness of the brass might be only 0.014" it still might be a problem getting it and the PTFE tubing through the rubber bushing that it needs to go through. So then I thought why not completely replace the short piece of PTFE tubing with brass tubing. Or better yet IMO copper tubing. But rigid copper tubing, not the flexible kind everyone is used too.

So I checked out the K&S web site and they have 5/32" OD brass tube. And 5/32" rigid copper tube too. And the ID is the same as the 5/32" PTFE tube, maybe a few thousands larger. Off to ACE (my favorite place) Hardware I go thinking they'll for sure have the brass tube but not so sure they'll have the copper. But they did.

Since I have no 3D printer to play with I then have plenty of time to fabricate a replacement part made out of copper tube for the short section of guide tubing that kinked. Below shows my efforts but more importantly my success! Not only was my 3D printer back up and running days before receiving the replacement PTFE tube, loading and feeding seems to be working much better. Whereas I would hear the occasional 'clicks' from the feed servo, I can say, not no more...

|

|

|

|

|

|

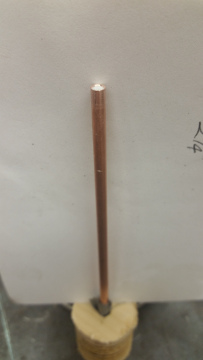

Copper tube filled and packed with salt and duct taped both ends so that the tube would deform less when bending it.

|

|

|

|

|

|

Bending a piece of 1/8" solid brass into a "U" that will be soldered onto the copper tube. It will serve to prevent the copper tube from being pushed up and out of the fitting which is what happened to the short section of the PTFE tubing.

|

|

|

|

|

|

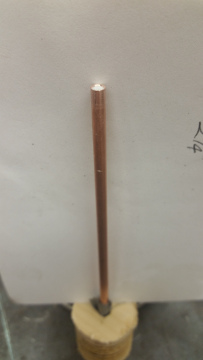

The completed replacement filament guide tube.

|

|

|

|

|

|

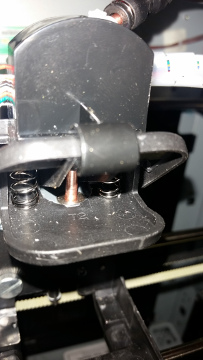

Close up of the completed replacement filament guide tube showing the brass "U". Once the "U" was soldered in place it was shaped by filing it with small round, convex, and flat files to custom shape it to fit and lock (vertically) the feed tube in place.

|

|

|

|

|

|

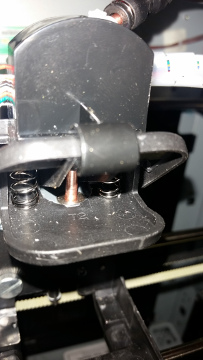

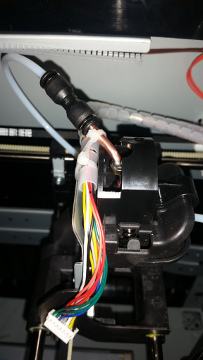

The replacement filament guide tube installed.

|

|

|

|

|

|

A top view close up of the replacement installed filament guide tube. Note how the brass "U" is under the boss of the hole in the top if the bracket therefore not allowing the tube to be pushed up.

|

|

|

|

|

|

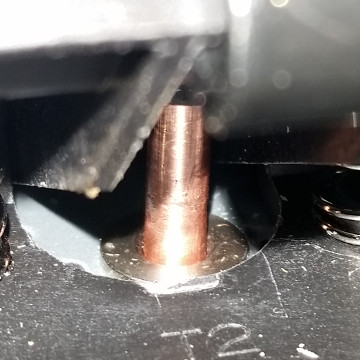

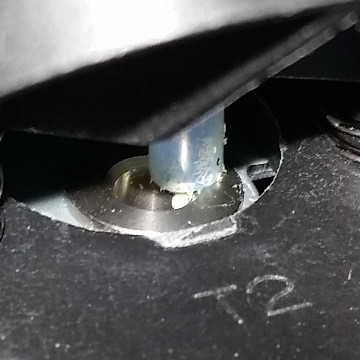

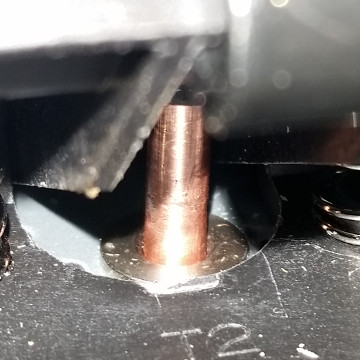

The copper tube seated in the lower fitting.

|

|

|

|

|

|

A close up of the copper tube seated in the lower fitting. The copper tube extends about 1/4" into that fitting. I believe the PTFE tubing was also inserted into the fitting but nothing really held it in the fitting.

|

|

|

|

|

Wider view of the replacement filament guide tube installed.

|

|

|

This has been superseded by

This has been superseded by